Aṅụ ihe ọṅụṅụ tupu usoro System

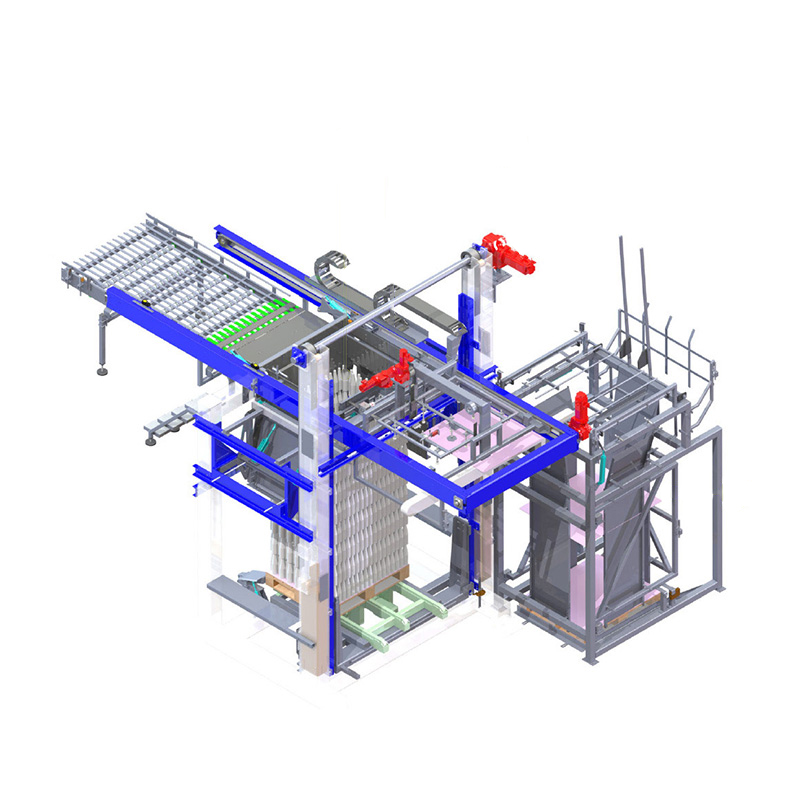

Nkọwa

Ihe ọṅụṅụ dị mma ga-enwerịrị ezigbo nri, uto, ụtọ na agba.Na mgbakwunye, anyị na-etinyekwu uche na ịdị ọcha na nchekwa nke ngwaahịa ihe ọṅụṅụ.Ngwa akụrụngwa dị elu, usoro pụrụ iche, teknụzụ dị elu, mana ọ dịkwa mkpa ịkwado akụrụngwa ọkaibe.Ngwọta na-emekarị na-agụnye nkwadebe mmiri ọkụ, mgbasa shuga, filtration, mixing, sterilization na, maka ụfọdụ ihe ọṅụṅụ, mmịpụta, nkewa, homogenization na degassing.Na n'ezie usoro CIP.

Atụmatụ

1. Nkwadebe mmiri na-ekpo ọkụ: Nye mmiri ọkụ maka shuga gbazere, ihe ọṅụṅụ / ihe enyemaka / usoro mbelata mmiri ara ehi.

2. Sugar dissolving usoro: Jiri ezigbo mma granulated sugar igbari na a ụfọdụ ego nke mmiri ọkụ na-eme ka sirop na-atụ anya itinye uche, na mgbe ahụ mgbe okpomọkụ nchekwa, sterilization, filtration, jụrụ na nchekwa maka ojiji.

3. Usoro ihe inyeaka: Nye obere ihe dị ka ihe ọṅụṅụ na-ebelata na stabilizer maka ntinye.

4. Usoro nkesa: kpochapu sirop niile, isi ihe ndị ọzọ na ihe inyeaka, ihe ọṅụṅụ na mmiri RO n'ime tankị na-enyefe iji dị ka ihe ndị a chọrọ nke usoro ntinye.Na tankị ngwakọta, kpalie, gwakọta nke ọma, nlele nlele.Mmiri mmiri na-eguzo ma dị njikere ibuga na usoro ọzọ.

5.CIP usoro: nwere ike na-aghọta ihicha usoro management, dị ka usoro chọrọ nke dị iche iche iche iche nke ihicha;Enwere ike ịdekọ mkpokọta, ọnọdụ okpomọkụ na paramita ndị ọzọ, nyocha oke kọmputa dabara adaba na ibipụta.

6. Extraction usoro: Akpaaka slagging nke mmịpụta akụrụngwa na-ghọtara site ya pụrụ iche mmịpụta tank Ọdịdị, nke mere ka mma mmịpụta arụmọrụ na nchekwa na ntụkwasị obi nke mmịpụta akụrụngwa na rụọ.Karịsịa adabara maka mmịpụta nke ihe ọṅụṅụ tii, ọ bụ ihe a pụrụ ịdabere na ya na nke dị elu.

7.UHT usoro (efere / tube ụdị): Dabere na ụkpụrụ na uche nke microorganisms na elu okpomọkụ dị ukwuu karịa nke ọtụtụ nri nri, ogo nke mmetụta na nri mma bụ nanị na nke kacha nta ọnọdụ, nke nwere ike ngwa ngwa. ma gbuo microorganisms dị na nri nke ọma ma chekwaa ogo nri.Ya mere, a na-eji UHT eme ihe na mmiri ara ehi, ihe ọṅụṅụ na ụlọ ọrụ ndị ọzọ na ọnọdụ okpomọkụ nke sterilization.

8. Ngwakọta igwe: Ngwakọta igwe na-emepụta site na ụlọ ọrụ anyị na-anabata usoro nhazi ezi uche dị na ya, nke nwere ike ịghọta nkwadebe nke ihe ọṅụṅụ nwere gas na-eguzosi ike na n'enweghị ihe ọ bụla, meziwanye àgwà, nkwụsi ike na ọrụ akpaka nke usoro dum nke usoro ahụ, ma nweta ngwaahịa na-abụghị nke afụ nwere ezigbo ngwakọta nke CO2, yana arụmọrụ dị elu.

Ngwaahịa dị iche iche chọrọ usoro dị iche iche iji mee ihe, iji nweta ngwọta kachasị mma maka ngwaahịa gị, biko kpọtụrụ anyị n'efu.